What’s so special about isol8’s Fusion® bonded-alloy barriers?

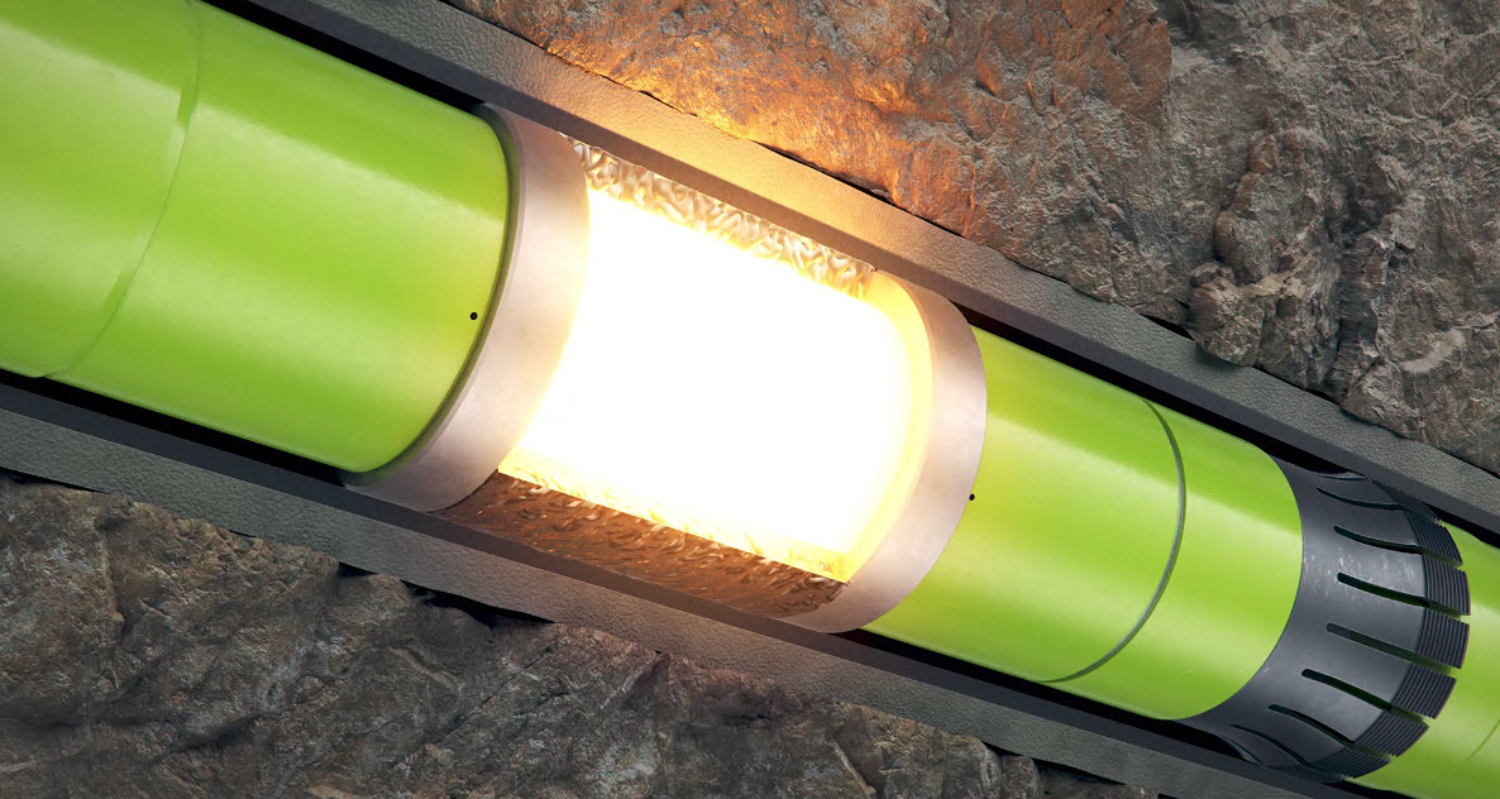

“The first question I often get asked is ‘Why should I use isol8’s bonded alloys rather than alternative technologies?’ That’s a great question. My first response is always to highlight the metallurgical bond that we create. isol8 is the only company to ‘fuse’ the alloy to the steel casing or tubing, hence the name Fusion®! And why is that such a big deal? Well, by creating a metallurgical bond between the alloy and the steel we deliver:

- The highest shear-bond strength of any barrier material on the market today

-

- >20 x shear-bond strength of the best cement, and

- >10 x shear-bond strength of unbonded alloys

In real terms, this means that a 4ft impermeable Fusion® bonded-alloy barrier has the same shear-bond strength as 100ft of cement. The best cements offer less than 300psi shear-bond strength, and unbonded alloys will typically deliver 500pst shear-bond strength – but we have tested isol8’s bonded alloys up to 6500psi.

- The greatest radial expansion capability of alloy-based barriers

We have devised a wholly unique method to melt alloy in large diameter annuli, with a patent pending on this revolutionary technique invented by isol8. It really is a game-changer for single and even multi-annulus well abandonment applications.

- The longest life expectancy with bonding created for eternity

As the in-situ stresses in an alloy relax over time, the metallurgical bond provides integrity assurance. Moreover, the rigless deployment options we offer can bring significant cost savings. Our alloy barrier material can also drastically reduce the environmental impact when it comes to well decommissioning, being a much lower emission solution than conventional cement-based plug & abaondoment approaches. Our bonded-alloy barriers can eliminate fugitive emissions from abandoned wells – for eternity.

Moreover, it can bring significant cost savings and reduced environmental impact when it comes to well decommissioning, being a much lower emission solution than conventional cement-based plug & abandonment approaches. Our bonded alloy barriers eliminate fugitive emissions from abandoned wells – for eternity.”

Get in touch to find out more about our pioneering bonded-alloy barrier solutions for the full well lifecycle, and how we can help you achieve significant cost savings with your decommissioning operations.

Posted: Feb 21, 2022

By: Andrew Louden